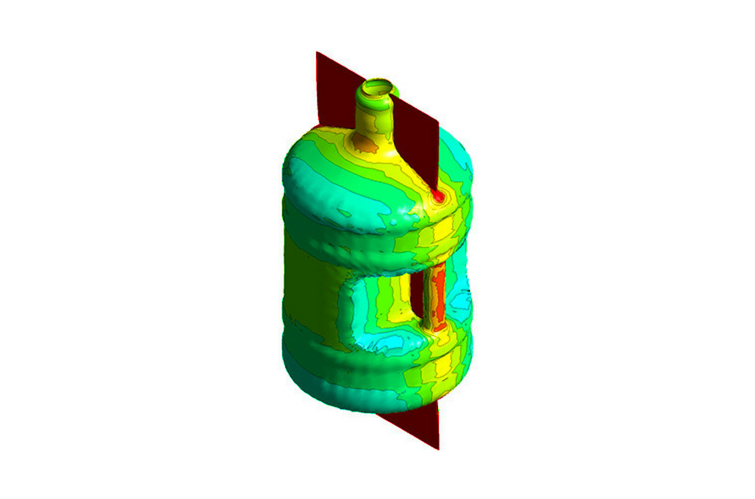

Polyflow accelerates design while shrinking energy and raw material demands to make your manufacturing processes more cost-effective and environmentally sustainable. R&D teams use this technology extensively to design and optimize processes such as extrusion, thermoforming, blowmolding, glass forming, fiber drawing and concrete shaping.

Design engineers use Polyflow to minimize physical prototyping when manufacturing extrusion dies or to reduce thickness variation to improve the quality of thermoformed or blown products.

More About ANSYS Polyflow

- Accurately capture flow domain deformations and robust solvers. Companies throughout the world in the polymer, glass, metals and cement processing industries reduce manufacturing risk by employing. ANSYS Polyflow as an integral part of their product design and optimization process.

Capabilities of ANSYS Polyflow

They use this proven technology to optimize extrusion, thermoforming, blow molding, glass forming, fiber drawing and concrete shaping.

Polyflow models your manufacturing process so you can take corrective action quickly and early in the process to cost-effectively design better, lighter packaging.

Native fluid–structure interaction (FSI) models thermomechanical interactions between flowing materials and surrounding solids in a fully coupled approach.

Polyflow includes a vast library of mathematical material models that aid in simulating materials so you can understand and accurately characterize material behavior.

Fine-tune your extrusion dies using PolyFlow to reduce the number of design iterations by 50 percent or more, saving resources and accelerating turnaround time.

Use Polyflow’s built-in optimization algorithm to automatically minimize or maximize a given objective function based on input parameters.

Polyflow includes models for advanced nonlinear material properties and radiation prediction for the most accurate simulation results.